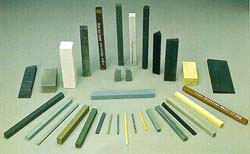

HONING STONES

Honing stones are manufactured

from high purity synthetic corundum (Aluminum Oxide) and Silicon

Carbide. We manufacture vitrified bonded as well as Bakelite bonded,

resin bonded, rubber bonded and PVA bonded honing stones depending

on the special applications of our customers. We have developed

special cool cutting bonds which provide high rate of stock removal

with a good finish. This cuts the production costs and eliminates

frequent dressing due to the self dressing property of our stones. Honing stones are manufactured

from high purity synthetic corundum (Aluminum Oxide) and Silicon

Carbide. We manufacture vitrified bonded as well as Bakelite bonded,

resin bonded, rubber bonded and PVA bonded honing stones depending

on the special applications of our customers. We have developed

special cool cutting bonds which provide high rate of stock removal

with a good finish. This cuts the production costs and eliminates

frequent dressing due to the self dressing property of our stones.

The

grit range is from 20 to 400 as per FEPA standards and sizes are

customised.

APPLICATIONS

:

Our stones are suitable for most

applications requiring Honing and are used in honing

- Hydraulic

and pneumatic cylinder

- Cylinder

Blocks and liners

- Hydraulic

equipment

- Gears

- Nozzles

- Pneumatic

Tools

- Gun

barrels of field guns and battle tanks

- Connecting

rod ends

- Guages

- Bushes

and bores

Our

Honing stones are made under strict quality control for the specific

need of a specific application.

SELECTION

:

It is important to select the right

stone for your application. If you need our assistance, please provide

us with the following initial information

- Type

of machine used and number of stones in a set.

- Machine

parameters like pressure, speed of rotation and reciprocation.

- Size

and material of component and its hardness

- Desired

material removal

- Initial

finish before honing

- Final

finish required

- Size

of honing stones

- Specification

of the presently used stone-if any and the areas in which the

improvement is required.

The

grit ranges from 46 to 400 as per FEPA. Stones can be supplied upto

800 as per JIS on request from customers. These are available in

rectangular cross section and can be supplied in any required shape.

RANGE

& SELECTION CODE :

| GC |

150 |

L |

5 |

V43 |

ST |

BA,

WA

PA, MA,

SA, BC,

GC, MC,

AC |

46,

54, 60, 80,

100, 120, 150,

180, 220, 240,

280, 320, 360,

400 |

D,

E, F, G, H,

I, J, K, L, M,

N, O, P, |

3,

4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 |

V-Vitrified

B-Resinoid

R-Rubber

P-PVS |

ST-Sulphur

WT-Wax

RT-Resin

T2-Shellac |

|